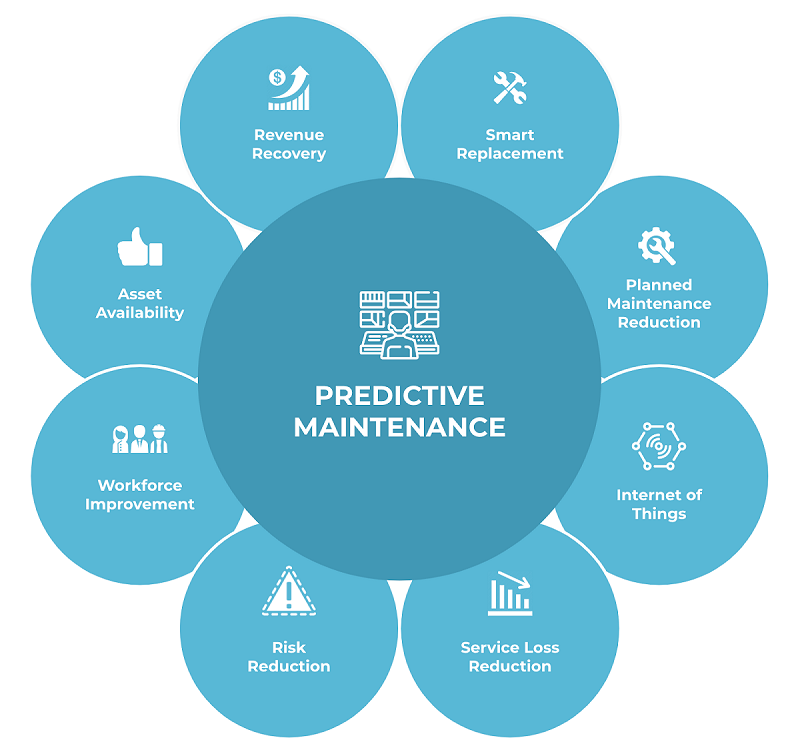

The Predictive Maintenance Market Value proposition is grounded in preventing unplanned downtime and turning emergencies into scheduled work. Unplanned failures are expensive: they stop production, create overtime, waste materials, and can damage upstream or downstream equipment. Predictive maintenance creates value by detecting degradation early enough to plan repairs, order parts, and coordinate labor during planned windows. This reduces lost output and avoids costly rush shipments. Value also includes improved asset lifespan, because equipment is maintained based on condition rather than arbitrary intervals. Another major value area is safety: preventing catastrophic failures reduces the risk of injuries and environmental incidents. Predictive maintenance also helps maintenance teams focus on the right work, reducing low-value preventive tasks and improving labor productivity. When applied to critical assets, these benefits can be large and measurable, strengthening the business case for broader deployments.

Value measurement typically starts with baseline metrics. Organizations track downtime hours, mean time between failures, maintenance cost per unit output, and the cost of reactive work. Then they measure improvements after deploying predictive models: fewer breakdowns, reduced emergency work orders, faster repair times, and better planning accuracy. In manufacturing, improved OEE can be tied directly to revenue and throughput. In energy and utilities, avoided outages and improved reliability metrics justify investment. Inventory value can also improve; with better prediction, firms can hold fewer expensive spares while ensuring availability for planned maintenance. However, value is not automatic. If alerts are too frequent or not actionable, teams ignore them and benefits vanish. Therefore, value depends on precision, clear recommended actions, and integration into maintenance planning. Strong governance—who validates alerts, how interventions are recorded—ensures learning and continuous improvement.

Stakeholder value differs across the organization. Operations leaders value stable production and fewer disruptions. Maintenance leaders value better scheduling, reduced overtime, and more predictable workloads. Finance teams value lower total maintenance cost and improved asset utilization. Safety and compliance teams value reduced incident risk and better documentation of inspections and interventions. Reliability engineers value better insight into failure modes and the ability to prioritize capital upgrades based on evidence. These perspectives reinforce that predictive maintenance is cross-functional. It must align operations, maintenance, IT/OT, and procurement. Investments may include sensors, connectivity, analytics software, and training. The best value cases focus on high-criticality assets where failures cause major downtime or safety risk. Once those wins are proven, organizations expand the program to less critical assets using templated approaches and lower-cost monitoring.

Over time, predictive maintenance value can compound as organizations build a reliability data foundation. Historical patterns improve models, and standardized work order feedback increases accuracy. Programs can evolve toward prescriptive maintenance, where systems recommend not only when to act but what action will prevent failure most effectively. Integration with production scheduling can further optimize maintenance timing. Sustainability benefits may also appear, as well-maintained equipment uses less energy and produces fewer defects and waste. The predictive maintenance market value story is therefore about operational resilience: fewer surprises, safer operations, and better cost control. Organizations that treat predictive maintenance as a long-term capability—supported by data governance, workflow integration, and skilled teams—capture the largest returns.

Top Trending Reports: